Summary

More transparent, more efficient and more tailored to individual needs: these were the requirements that BOSIG GmbH placed on software for controlling and tracking all business processes. Previously, different processes and systems existed in parallel for different business transactions. Due to these confusing structures, internal resources could not be managed effectively.

The implementation of the MSO action/workflow manager provided a remedy here. Since then, BOSIG has been able to coordinate every measure and every process in an integrated system in a comprehensible, transparent and simple manner at all times. The result: noticeably more efficiency and greater employee and customer satisfaction thanks to transparent and reliable processes and improved process tracking.

Background

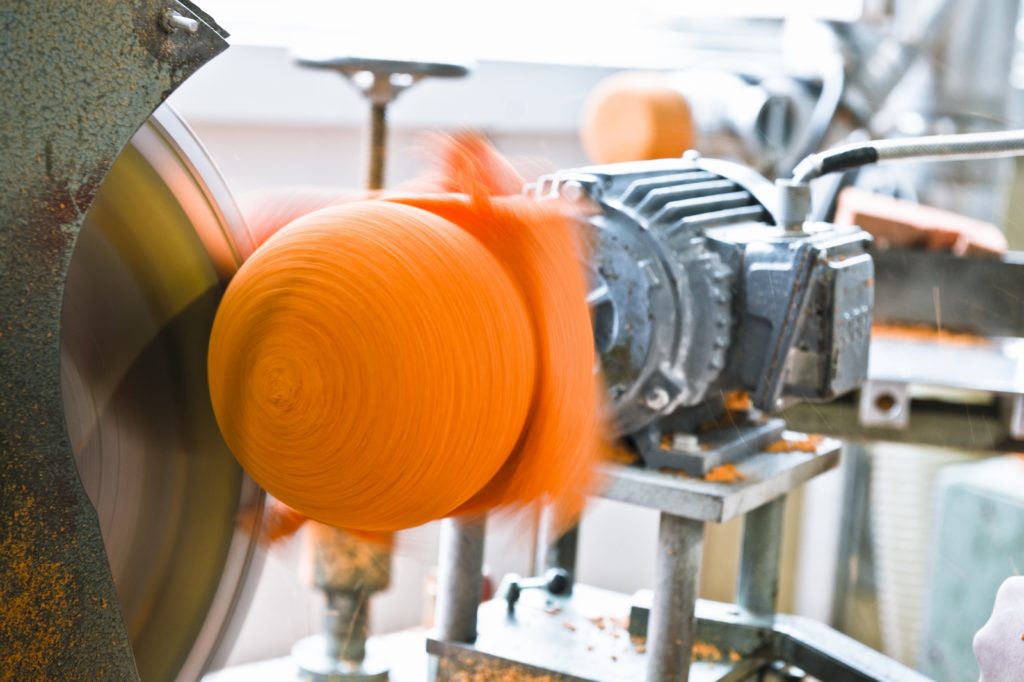

With its building materials for sustainable construction, BOSIG GmbH is one of the market leaders in Germany and sells its products within the European Union, but also increasingly on the Asian market. As BOSIG develops, produces and sells product solutions for many different sectors – e.g. residential, structural, industrial, roof, window, door and mechanical engineering, special vehicle construction, acoustics, etc. – it is important to maintain an overview of the complex product and process structure at all times.

This cannot be easily mapped with simple, less flexible software. The management therefore approached MSO Solutions with the very specific request to introduce a software solution that would enable comprehensive control and tracking of all business areas and processes.

It was important to BOSIG’s management to be able to coordinate the various processes within the company in a central tool. They were looking for a system that could be configured precisely to the needs of the medium-sized company and that could be constantly adapted accordingly. Without additional programming or IT effort and the associated costs.

Before the introduction of central management software from MSO, the processing status of individual processes and measures could not be viewed or only with difficulty, the workload of individual departments or employees could not be tracked and therefore the necessary resources that the company actually needed could not really be calculated on the basis of the necessary data.

Solution

Therefore, the goal set by BOSIG’s management was that the new software should enable centralized control of processes and measures in almost all areas of the company. At this point, it was also essential to ensure full compliance with the German Federal Data Protection Act in force at the time of implementation, today with the European General Data Protection Regulation, the requirements of BOSIG GmbH’s certifications (ISO 9001, ISO 14001, OHSAS 18001 and ISO 50001) and the internal compliance regulations.

MSO was also chosen because no complex additional installations are required to use the web-based management software. All functions can be operated intuitively in the browser. Managing Director Harry Leichmann cites proximity to the customer as the main reason for the decision to use MSO throughout the company:

“MSO Solutions’ holistic view of the concerns and needs of its customers has impressed us for more than a decade. Thanks to the trusting cooperation, we have not only been able to plan goals together, but also achieve them. Many individual activities have become one big, successful WHOLE.”

The MSO Action Manager is now used to control a large number of processes in the company:

From development projects to PDCA measures (a method for the continuous improvement of quality management or the entire company), internal and external maintenance orders, interim orders for production and employee training through to the allocation of company vehicles, the individual departments benefit from efficient and structured workflows. Automated e-mail notifications and a wide range of reporting functions mean that, for the first time in the company, individual processes can be compared and the achievement of certain KPIs can be continuously monitored

Benefits

With the help of the MSO management solution, BOSIG has been able to simplify or optimize many different processes – including change proposals for the process model, the commissioning of external companies, development projects, customer or supplier complaints, marketing projects, PDCA measures, quality checks, repair measures, damage claims at forwarding agents, training courses, reservations of company vehicles, production orders and much more.

Collaboration within the organization has also changed: Before the introduction of MSO, there were different processes and systems for different business transactions.

A large part of the organization functioned via the mail system. However, many other smaller systems were also used in parallel.

MSO’s software ensures that the processing status of individual processes or measures can be checked and transparently tracked at any time. Evaluations provide an overview of the development of corporate goals and key figures, the performance of processes and the degree of implementation of CIP measures. “For us, MSO means more transparency, traceability and processing speed,” emphasizes Harry Leichmann.

The return on investment for BOSIG consists of time savings, greater transparency, a better overview and faster throughput times. According to the employees, the perceived workload within the individual departments has decreased at the same time.

MSO also has a direct impact on customer satisfaction: faster processing of complaints is an explicit consequence of the introduction of the software. Thanks to the improved overview of the utilization of individual areas, the more efficient provision of resources and the resulting reduction in machine downtimes, BOSIG can significantly shorten production cycles across the entire product range.

With the introduction of MSO, all these processes were standardized and various systems were consolidated, minimizing the administrative workload for all employees and making day-to-day work more efficient. Thanks to the central recording of processes and measures, there is now a standardized system that all employees can use as a guide. All decision-making processes are transparent and comprehensible. The result: internal conflicts decrease and the level of satisfaction increases.

Prospect

The individually configurable MSO software is currently in use in all departments of the company. The solution is constantly being further developed in dialog with employees and continuously adapted to changing needs. Employees are constantly providing new ideas and suggestions for new features. At the top of this list is integration into the mail system calendar so that due dates and appointments can be displayed directly there and the relevant topics and tasks can be edited.

A link with the mail system – in particular with the calendar – appears to make sense, as the scheduling of measures can then be coordinated even better with other appointments in the calendar. The developers at MSO are currently working on a technically feasible solution.